Call Us : 08045479074

HDPE Pipe Butt Welding

100.00 - 200.00 INR/Meter

Product Details:

X

HDPE Pipe Butt Welding Price And Quantity

- 500 Meter

- 100.00 - 200.00 INR/Meter

HDPE Pipe Butt Welding Trade Information

- Mumbai

- 10 Meter MT Per Day

- 3-4 Days

- Yes

- standard

- Eastern Europe, Western Europe, Africa, Asia

- All India

- ISO ,ISI,

Product Description

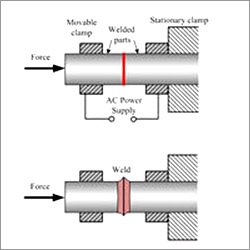

We offer our clients with butt welding of HDPE, PP, PVDF, LDPE & MDPE Pipes & Fittings. The HDPE Pipe Butt Welding is done with the use of hot plates and hydraulic jacks & aligners for higher diameter pipes. We carry turnkey job work for on site butt welding through a very specialised and well trained & skilled team.It is offered in customized options to our clients in their specific requirements.Application areas Of Butt Welding:

- Water & gas Pipe lines

- Chemical industry Pipeslines

- Electric conduits

- Sewerage lines etc.

Precision in Pipe Joining

Our HDPE pipe butt welding service employs precise fusion temperature controls, ensuring consistently strong and durable joints. This welding approach is ideal for projects demanding reliability and longevity, such as water supply, sewage systems, and gas distribution networks. With a robust operating temperature range, it is adaptable for both indoor and outdoor installations.

Versatile Applications & Superior Performance

Suitable for potable water, chemical transmission, agriculture, and industrial sewage systems, these HDPE pipes are crafted to excel in demanding environments. Butt fusion welding delivers a seamless, smooth surface, optimizing flow and reducing the risk of leaks, even under fluctuating pressure and temperature conditions.

FAQs of HDPE Pipe Butt Welding:

Q: How is HDPE pipe butt welding performed?

A: HDPE pipe butt welding is done by aligning the ends of two pipes and heating them to a fusion temperature range of 200C220C. Once softened, the ends are pressed together and allowed to cool, forming a joint that is as strong as or stronger than the pipe itself.Q: What are the main benefits of using HDPE pipe butt welded joints?

A: Butt welded joints in HDPE pipes provide exceptional strength, seamless leak-proof connections, and excellent resistance to corrosion. The smooth and uniform weld enhances flow and reduces maintenance needs, making it a reliable choice for various applications.Q: When is butt fusion welding the preferred method for HDPE pipe joining?

A: Butt fusion welding is preferred when a permanent, high-strength, and leak-free connection is required, such as in potable water supply networks, chemical processing lines, agricultural irrigation, and gas distribution systems.Q: Where can HDPE pipe butt welded connections be utilized?

A: These connections are suitable for indoor and outdoor installations in potable water pipelines, chemical transfer systems, agriculture, sewage, and gas distribution, adaptable to a broad temperature range from -40C to 60C.Q: What is the process to ensure leak-proof and uniform surface finish in HDPE pipe welding?

A: The process involves precise temperature control during heating, accurate pipe alignment, and regulated cooling, which together guarantee a strong, smooth, and leak-proof joint that matches or exceeds pipe strength.Q: What makes HDPE pipe butt welding suitable for corrosion-prone environments?

A: HDPE material is inherently resistant to chemical and environmental corrosion, and butt fusion welding eliminates joints or fittings where leaks typically occur, providing robust, long-lasting performance even in aggressive conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pipe Welding Solutions' category

|

DARSHAN PIPES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |