Call Us : 08045479074

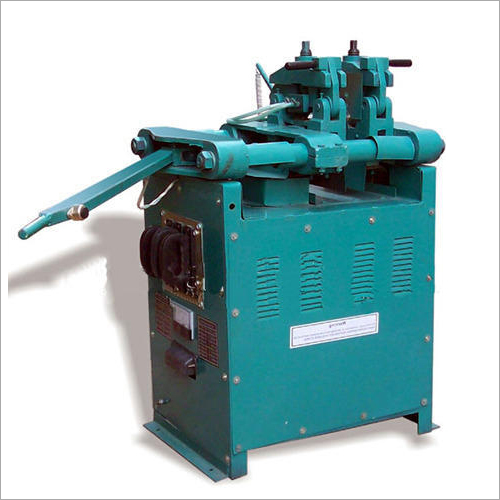

Butt Welding Service

300.00 - 400.00 INR/Meter

Product Details:

X

Butt Welding Service Price And Quantity

- 2000

- 300.00 - 400.00 INR/Meter

Butt Welding Service Trade Information

- 10000 Per Week

- 3-4 Days

Product Description

Our Butt Welding Service specializes in joining two pieces of metal at their ends to create a seamless, strong connection. Our team of skilled welders utilizes the latest welding technology and techniques to ensure the highest quality results. Our services are suitable for various industries, including construction, manufacturing, and transportation. We work with a wide range of materials to meet your specific project requirements. Our commitment to safety and quality is unmatched, and our Butt Welding Service will benefit your business.

| Welding Type | Butt & Electrofusion Welding |

| Service City | All over India |

| Dimension / Size | 20 - 1000 mm |

| Automatic Grade | Automatic |

| Capacity | 20 - 1000 mm |

| Range of Welding | 2.5 KG to 20 Kg/Cm2 |

| Application | Water & Chemical industry Pipeslines |

Extensive Welding Capabilities

We offer butt welding for pipes with diameters up to 1200 mm and thicknesses up to 50 mm. Our expertise covers various materials, including stainless steel, mild steel, and alloy steel, making us a versatile choice for industrial, construction, and pipeline applications. Advanced welding techniques, both manual and semi-automatic, are utilized to achieve the highest quality results.

Quality Assurance and Inspection

Ensuring the integrity of every weld, our service includes post-weld inspections using ultrasonic or radiographic methods. Stringent quality standards are maintained throughout the process, and detailed test certificates are provided to clients upon completion. This approach guarantees not only compliance with industry norms but also optimal safety and reliability.

FAQ's of Butt Welding Service:

Q: How is the butt welding process carried out for large diameter pipes?

A: We utilize both manual and semi-automatic techniques to perform butt welding on pipes with diameters up to 1200 mm and wall thicknesses up to 50 mm. The process involves aligning the pipe ends, applying heat, and fusing them to form a strong, seamless joint. Skilled technicians ensure that weld quality and desired surface finish meet industry specifications.Q: What materials can be welded using this butt welding service?

A: Our service is equipped to handle stainless steel, mild steel, and alloy steel. These materials are commonly used in industrial, construction, and pipeline connections, and our team selects the best welding parameters specific to each material for optimal results.Q: When are post-weld inspections conducted, and what methods are used?

A: Post-weld inspections are performed after the welding process is completed. We employ advanced non-destructive testing methods such as ultrasonic and radiographic inspection to verify weld integrity and ensure the highest quality for every project.Q: Where can your butt welding service be availed, and is on-site support provided?

A: Our butt welding services are available pan India. We offer both on-site and in-house solutions depending on the project scope and client needs, ensuring flexibility and convenience for our customers.Q: What are the benefits of using this butt welding service for pipeline connections?

A: Our service offers high joint strength, excellent heat-affected zone control, and a smooth surface finish, resulting in durable, leak-proof connections ideal for pipelines. Comprehensive quality checks and adherence to industry norms also enhance overall system safety and longevity.Q: Is customization available to meet specific client requirements?

A: Yes, we provide customized butt welding solutions tailored to client specifications, including special welding parameters, inspection documentation, and material selection. If you need a unique solution, our team will collaborate closely with you to address your requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Welding Services' category

|

DARSHAN PIPES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |