Call Us : 08045479074

Extrusion Welding

100.00 - 200.00 INR

Product Details:

X

Extrusion Welding Price And Quantity

- 100.00 - 200.00 INR

- 500 Meter

Extrusion Welding Trade Information

- Mumbai

- 10 Meter MT Per Day

- 3-4 Days

- Yes

- standard

- Eastern Europe, Africa, Western Europe, Asia

- All India

- ISO ,ISI,

Product Description

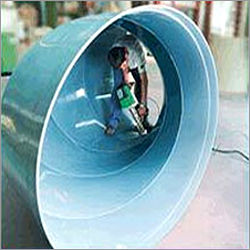

We offer our clients with a recognized technique for the fabrication of assemblies from thermoplastics. It is mainly used for polyethylene and polypropylene using welding rods and sophisticated torches & machines. Some of the applications of the process use nylon but good care must be taken to dry the welding rod to prevent voids occurring in the weld. Other applications include the fabrication and repair of old & new pipelines, tanks, canopies, pipe fittings, liners for refuse tips and lakes.Product Details Of Extrusion Welding:

| Product type | Extrusion Welding |

| Application | Gas Pipe,Hydraulic Pipe |

| Brand | Shree Darshan Pipes |

| Material | Polyethylene and polypropylene |

| Usage | PE and PP using welding rods and sophisticated torches & machines |

Versatile Welding for Thermoplastic Applications

The extrusion welding machine supports a diverse range of projects, from plastic fabrication and tank manufacturing to pipe and duct work. Interchangeable nozzles facilitate customized weld profiles, making it adaptable for HDPE, PP, and PVC materials. Its controlled extrusion temperature range of 180C to 300C ensures reliable joints across multiple thermoplastic tasks.

Integrated Digital Control and Safety Systems

Equipped with digital temperature control and an integrated safety shutoff, the machine allows precise setting and monitoring of welding temperatures. Overheat protection and an insulated handle further safeguard users during operation. These advanced features collectively promote consistent welding quality and operator comfort while minimizing risk.

FAQs of Extrusion Welding:

Q: How does the digital temperature control system enhance extrusion welding?

A: The digital temperature control system enables precise regulation of welding temperatures, ranging from 180C to 300C. This precision ensures optimal melting and joining of thermoplastic materials, improving weld strength while reducing the risk of overheating and material degradation.Q: What materials can I weld with this extrusion welding machine?

A: This machine is suitable for welding thermoplastics such as HDPE, PP, and PVC. It supports a variety of applications including tank construction, ductwork, and plastic fabrication, providing strong and consistent welds for these material types.Q: When is air supply necessary during the welding process?

A: An external air supply is required to facilitate the extrusion welding process. It helps maintain the correct flow and temperature of the welding material, which is essential for achieving uniform welds and optimal output rates (2.06.0 kg/hr).Q: Where is this extrusion welding machine best utilized?

A: The machine is ideal for use in workshops, factories, and construction sites engaged in plastic fabrication, tank building, and pipe/duct installations. Its robust design and portable weight make it suitable for both on-site and off-site operations in India.Q: What benefits do interchangeable nozzles offer for different weld profiles?

A: Interchangeable nozzles allow users to modify weld profiles according to specific project requirements, achieving tailored weld seams for various shapes and applications. This flexibility maximizes machine utility across a broad range of thermoplastic fabrication tasks.Q: How does the machines safety system protect the user?

A: Safety features include overheat protection, an insulated handle, and an integrated safety shutoff. These systems continuously monitor operating conditions, preventing accidental burns and equipment damage; thus ensuring the operators safety throughout usage.Q: What is the process for using different welding rod diameters?

A: Operators can select welding rods between 3 mm and 5 mm in diameter based on weld requirements. Insert the appropriate rod into the machine, set the desired temperature via the digital control, and allow the integrated heating element to prepare the material for extrusion welding.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pipe Welding Solutions' category

|

DARSHAN PIPES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |